Hey! There is a closer and better look at what is flux and how to use flux for soldering during the process of soldering electronic components into circuit boards, as if the surface of the metal is not properly dry, clean, and ready to be soldered, we might not be able to get a better and lasting bond between the metals.

What is Flux?

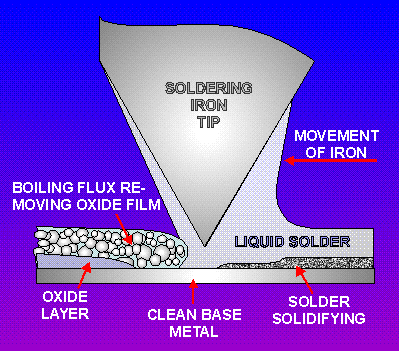

Soldering Flux or Flux is a chemical cleaning substance that is used for the soldering process of various electronic parts or components to circuit boards during or before the process of soldering. Flux basically removes the oxide layer from the surface of the component which is being soldered and also prevents the new oxide layer from forming again.

It basically makes it easy to combine the molten soldering components with electronic devices. The usage of flux for soldering is good as it makes the stronger bond between both surfaces of metal.

What is flux used for in soldering?

- The primary function or purpose of using flux is to make the surfaces of metal ready for the process of soldering by removing impurities and oxides from them.

- It also makes shields around the surfaces of metal in order to stop further oxidation before or during the soldering process.

- It also reduces the intensity of viscosity and surface tension of molten solder.

- The purpose of using flux also includes making a permanent or long-lasting joint of an electrical and mechanical nature.

How to use Flux?

The simpler procedure and process of using flux for soldering are written below which can be used with proper caution and instructions:

- The surface of metals should be properly cleaned and dry before using the soldering flux with any suitable solvent in order to remove impurities, extra oxidation (if any), and dust from the surface of metals.

- Then, apply a layer of flux at the desired place where soldering of metal surfaces has to be done, taking proper precautionary measures.

- The layer of flux then should be applied to the metals when the soldering gun is ready to make the bond between the surfaces of the metal. The soldering gun should melt the flux.

- Then, the soldering wire should be kept close to the surface once the flux has evaporated. There should be deep caution that a bond has formed between the surfaces of metal before its re-oxidation.

Types of Soldering Flux

There are primarily three kinds of soldering flux on the basis of electronics industry standards, which is as follows;

1. Rosin Flux

It is one of the ancient and still common fluxes. The base materials of this flux are extracted from pine tree resin. It is usually in a solid state when it is inert. It becomes acid when heated and usually, it flows. It helps in removing oxides and remaining particles from the metals. Furthermore, it can be cleaned with the solution of isopropyl alcohol. After the usage, the excess residue should be removed as earlier as possible.

2. Organic Acid Flux

Organic acid flux is also called water-soluble flux. The organic flux is comprised of organic substances along with rosin. Unlike rosin flux, the organic flux is stronger and cleaner in nature as compared to rosin flux.

The organic acid flux requires more precautionary cleaning when it is applied because it is corrosive in nature. If the excessive flux is not cleaned after application to the surface of metals, it may lead to even short circuits due to poor performance of various components. Organic acid flux may be washed with water.

3. Inorganic Acid Flux

The inorganic acid flux is comprised of various chemical substances like chlorides, fluorides, and borates. The inorganic flux is generally used for stronger metals such as brass, stainless steel, copper, etc. The inorganic acid flux is usually not recommended for electrical circuits due to its power or strength. Mainly, the inorganic flux is used for the plumbing. The inorganic acid flux is extensively corrosive in nature and even its very minute residue may destroy a solder connection.

Conclusion

It is evident from the above facts that the soldering flux is a very essential substance that can be used in the process of electrical soldering. The process of soldering flux also helps to remove the layer of oxides before and during the process and it also prevents further oxidation on the surfaces of metals. It also develops a stronger bond between the metals through the soldering process.

If you have any queries or need more guidance and information regarding the process of soldering flux, then feel free to contact us. We would be happy to solve your queries.